SEOUL, January 20 (AJP) - Humanoid robots have become a buzzword at CES and beyond, captivating both technology and stock markets as artificial intelligence converges with China's formidable manufacturing power.

This emerging breed of "robo sapiens" joining humanity — at least in its first generation — is, in essence, a two-legged electric vehicle with a brain.

That reframing is not rhetorical. As humanoids move from laboratories toward commercialization, engineers, investors and policymakers are increasingly abandoning the idea of robots as walking computers and instead treating them as mechanical systems: complex assemblies of motors, joints and power units governed by AI.

This shift helps explain why automakers have emerged as the industry's most promising producers — and why Hyundai Motor Group's humanoid robot Atlas captured the Best Robot title at CES 2026.

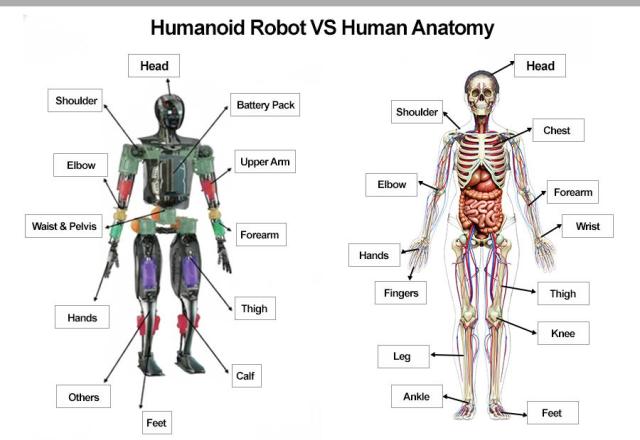

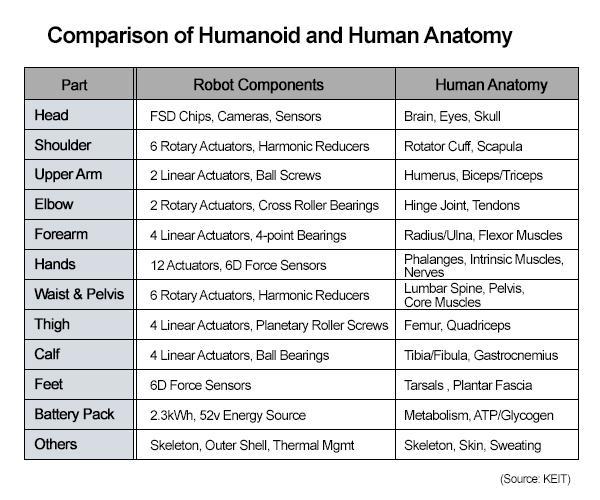

"When you break down a humanoid by hardware, you have the head and neck, the torso, the upper body including the arm system, and then the hands at the end," said Park Dong-il, director of the Advanced Robotics Research Center at the Korea Institute of Machinery and Materials.

"It's essentially the same anatomy as a human, and each part requires its own actuators, sensors and control mechanisms."

The EV connection

Both industries depend on high-density lithium-ion batteries, precision actuators and advanced motor technology. Both face supply-chain constraints around rare-earth elements required for permanent magnets. And both are racing to reduce costs through economies of scale.

Hyundai Motor Group, which acquired Boston Dynamics for $880 million in 2021, plans to have affiliate Hyundai Mobis supply actuators for the Atlas humanoid robot. The group aims to produce 30,000 robots annually by 2028, leveraging the same manufacturing infrastructure and supplier networks that underpin its vehicle business.

Tesla, meanwhile, has promised to unveil the third generation of its Optimus humanoid robot early this year. Elon Musk has suggested the bipedal robot could even become "an incredible surgeon."

"Imagine if everyone had access to an incredible surgeon," Musk said. "Of course, we need to make sure Optimus is safe and everything. But I do think we're headed for a world of sustainable abundance."

Industry experts identify Hyundai, Tesla and China's XPeng Motors as the current frontrunners among automakers entering robotics. While Xiaomi, BYD and Li Auto have also announced humanoid ambitions — often using autonomous driving data to train AI models — the top three are seen as the only players capable of near-complete in-house robot production.

"Google and Nvidia chose Boston Dynamics as a partner for a reason," said Yim Eun-young, an analyst at Samsung Securities. "Hyundai's factories generate real-world behavioral data, continuous datasets that adapt to changing environments, and actual production and logistics sites where robots can be deployed and validated."

"Most other robotics firms are startups," she added, "and they lack the infrastructure to accumulate large-scale behavioral data or test machines in real-world conditions."

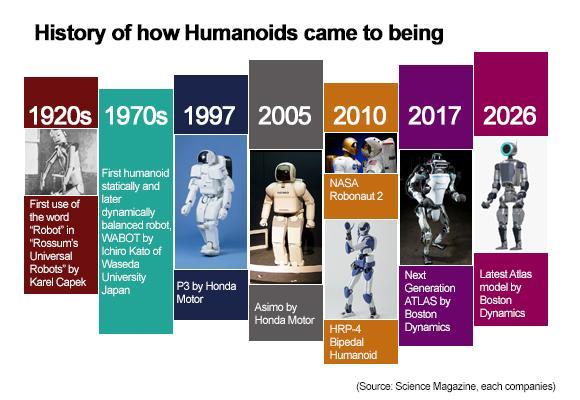

Despite more than half a century of development, no international standard defines what constitutes a humanoid robot.

Nvidia, whose processors power the vast majority of humanoids currently under development, offers a working definition:

"Humanoids are general-purpose, bipedal robots modeled after the human form factor and designed to work alongside humans to augment productivity."

Yet in practice, the term encompasses machines with widely divergent designs — from full bipedal bodies to human-like torsos mounted on wheeled bases — many of which do not neatly fit Nvidia's description.

"The definition of 'humanoid' itself is still unclear," Park said. "There's no ISO standard. We call robots with only an upper body humanoids, and we also call robots with both upper and lower bodies humanoids."

The ambiguity extends further. Must a humanoid have five-fingered hands? Boston Dynamics' production Atlas uses a three-fingered gripper. Must it walk on two legs? Several robots showcased at CES 2026, including LG Electronics' CLOiD, used wheeled bases.

And what about the face? From Unitree's G1 to UnixAI's Wanda series, most humanoids opt to remain faceless. Yet companies such as Realbotix and Engineered Arts argue that facial expressions are essential for natural human-robot interaction.

According to discussions at the 2025 Humanoids Summit in London, industry groups are now debating whether the term "humanoid" should be replaced altogether with classifications based on capability rather than appearance.

Two ways to map the machine

The mechanical approach breaks humanoids into physical subsystems — head and neck, torso, arms, hands, waist, legs and feet — each requiring dedicated actuators, sensors and control systems. The logic mirrors how an EV is analyzed through its battery pack, motor, inverter and chassis.

Lee Jun-yong, a senior researcher at the Korea Planning & Evaluation Institute of Industrial Technology (KEIT), adopted a different perspective when authoring a government report on humanoid R&D in February 2025.

His team consulted futurists, economists and social scientists to envision how humanoids might integrate into society by 2040, then worked backward to identify the technologies required to make those scenarios viable.

The framework identified 10 core technologies across four domains: motion control, sensing, human-robot interaction and drive/control systems.

"We started by envisioning future society and then identified the technologies needed to reach it," Lee said.

"Deciding whether the government should directly lead humanoid development or support private-sector R&D is complicated, because robotics spans so many industries. Household robots that truly help people are still far off, which is why we felt a top-down approach was essential."

The market acceleration

Elon Musk offered a far bolder forecast at the Future Investment Initiative conference in Saudi Arabia in October 2024, predicting 10 billion humanoid robots by 2040 at prices between $20,000 and $25,000 each.

Many robotics researchers remain skeptical, noting that a single universally capable robot is unlikely within that time frame.

Cost remains a major constraint. Investment banks including J.P. Morgan estimate that Boston Dynamics' Atlas will cost at least $130,000 per unit when mass production begins around 2030. The prototype currently costs about $300,000 to build, with the commercial target set at less than half that figure.

That remains five to six times higher than Tesla's stated goal of producing Optimus robots at $20,000 to $30,000 each.

Still, the industrial logic is taking hold. If humanoid robots are indeed EVs with brains, then the automotive playbook — mass production, supply-chain integration and incremental cost reduction — applies directly.

Park cautioned that the field is evolving too rapidly for fixed definitions or confident forecasts.

For now, the working definition remains broad: machines with human-like form designed to operate in environments built for people. Whether that form requires legs, fingers or a recognizable face may ultimately be decided not by standards committees, but by the factories — automotive and otherwise — that build them.

Lee's KEIT report ends with a provocative question: will humanoids one day demand labor rights as they replace human workers with tireless, uninterrupted productivity?

"Our futurists raised the possibility that robots could eventually replace low-cost labor entirely," Lee said. "If overworked, they might malfunction — or even terminate their own digital existence. Who knows what the future holds?"

Copyright ⓒ Aju Press All rights reserved.