SEOUL, January 26 (AJP) - South Korean researchers have built an AI system that predicts how to make better batteries, even when the data from previous lab tests is messy or incomplete. This new tool helps scientists skip the long, expensive process of trial and error by figuring out the best recipe for battery materials before they ever step into the lab.

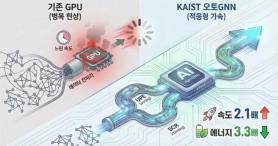

The Korea Advanced Institute of Science and Technology (KAIST) announced on January 26 that a team led by Professor Hong Seung-bum and Professor Jo Eun-ae developed this machine learning framework. It focuses on the cathode, the part of the battery that acts like a tank for storing energy. In most electric vehicles today, this tank is made of a mix of nickel, cobalt, and manganese, commonly called NCM.

The secret to a long-lasting battery often lies in the size of the tiny particles that make up the cathode. If these particles are too big, the battery struggles to charge and discharge efficiently. If they are too small, the battery can become unstable. Finding the right size is essential for making electric cars go further and smartphones last longer.

Until now, scientists had to spend months baking materials at different temperatures and for different amounts of time to see what size particles they would get. To make matters worse, lab records are rarely perfect. Sometimes a researcher forgets to record a temperature, or a measurement is missed, leaving gaps in the data that make it hard for traditional computers to learn the pattern.

The South Korean team solved this by creating a two-part AI system. The first part, called MatImpute, acts like a smart autofill. It uses the laws of chemistry to guess what the missing lab data should have been. The second part, a model called NGBoost, then predicts the final particle size. What makes this AI different is that it does not just give a single answer; it also tells researchers how sure it is. For example, it might say, "I am 95 percent certain the particles will be this size." This helps scientists decide which experiments are actually worth their time.

When the researchers tested the AI, it was right about 86.6 percent of the time. They even tried it on four brand-new recipes that the AI had never seen before. The AI predicted the particle sizes with an error of less than 0.13 micrometers, a distance much thinner than a human hair.

The study showed that the way a material is cooked, including the temperature and time, actually matters more than the specific chemical ingredients when it comes to particle size. This insight will allow researchers to develop next-generation batteries, like all-solid-state versions, much faster than before.

The research was led by Benediktus Madika, a doctoral student at the Korea Advanced Institute of Science and Technology, and was published in the journal Advanced Science on October 8, 2025. The project was supported by the Ministry of Science and ICT.

(Paper information)

Journal: Advanced Science Title: Uncertainty-Quantified Primary Particle Size Prediction in Li-Rich NCM Materials via Machine Learning and Chemistry-Aware Imputation DOI: https://doi.org/10.1002/advs.202515694

Copyright ⓒ Aju Press All rights reserved.