[Courtesy of KRICT]

Just after a COVID-19 pandemic erupted in early 2020, the global demand for face masks skyrocketed. The key manufacturing countries of disposable face masks including China and South Korea have seen an explosive increase in orders, according to global market research firm Research and Markets. The global face mask market is projected to reach $31.8 billion by 2027.

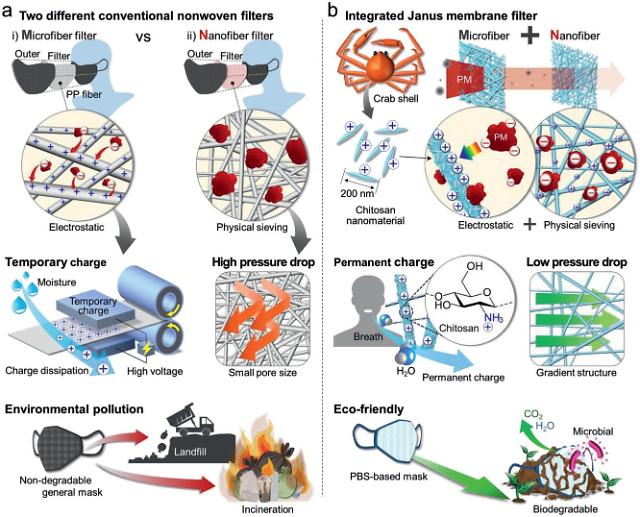

Face masks have become an everyday necessity to help prevent the spread of COVID-19, but they caused a waste problem. Filtered masks that were produced using plastic materials are not recyclable or degradable. They have to be sorted from other garbage and incinerated.

The Korea Research Institute of Chemical Technology (KRICT), a state research center, said in a statement on March 22 that its research team has developed a mask filter made with polybutylene succinate (PBS), a biodegradable plastic material, that is 100 percent decomposable in four weeks in composting soil.

The high-performance fibrous mask filter is biodegradable, moisture-resistant, and highly breathable, the institute said, adding the filter is efficient as the commercial N95 model that removes 98.3 percent of microscopic materials floating in the air.

While PBS material is weak against moisture, the researchers coated the mask filter with cationically charged chitosan nanowhiskers. As a result, the filter is multi-usable. Chitosan is a material that is made by treating the chitin shells of shrimp and other crustaceans with an alkaline substance. "It was not hard to develop a product that can be commercialized as we decided to adopt a domestically developed chitosan-coating technology.

KRICT's research was published through the January 29 2021 issue of Advanced Science, an international scientific journal.

Copyright ⓒ Aju Press All rights reserved.