[Courtesy of LG Energy Solution]

SEOUL -- The battery-making wing of South Korea's LG Group developed innovative technologies that can advance the commercialization of all-solid-state batteries that use composite-type solid electrolytes instead of liquid electrolytes, using micro-sized silicon particles which are comparatively cheap and easy to use.

All-solid-state batteries are seen as a next-generation power source for electric vehicles as solid electrolytes are nonflammable and more stable. They can have a higher energy density than lithium-ion batteries. However, all-solid-state batteries using lithium as an anode to improve energy density can only be charged in high-temperature environments and their charging speed is slow.

In a joint study with the University of California San Diego, LG Energy Solution (LGES) claimed to have developed an all-solid-state battery with a long lifespan that can be charged at high speed even at room temperature. The company said this is the first all-solid-state battery to have a charge and discharge life of more than 500 times at room temperature.

"We are one step closer to commercializing all-solid-state batteries that are spotlighted as next-generation batteries," chief procurement officer Kim Myung-hwan said in a statement on September 24.

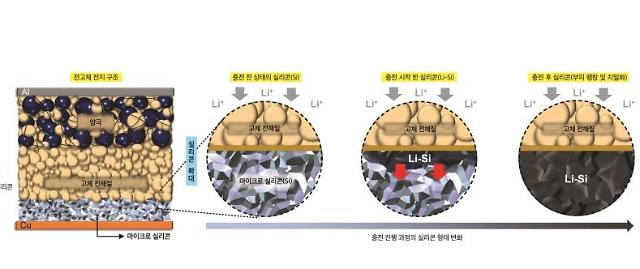

An electrode is made of conductive materials, solid electrolytes, active material for energy storage, and binders that physically and chemically harness all parts. LGES said that researchers removed conductive materials and binders to apply a micro-silicon material that can achieve a higher capacity than graphites. It was possible to maintain a remaining capacity of more than 80 percent after charging and discharging more than 500 times and to increase energy density by about 40 percent compared to commercialized lithium-ion batteries.

Battery suppliers are trying to develop cheaper, more efficient, and more powerful batteries. Compared to flammable liquid electrolytes, solid-state batteries have a lower risk of catching fire. Fewer safety systems are needed, further increasing energy density. German auto giant Volkswagen has unveiled a massive push to reduce the cost of producing batteries and eventually switch to solid-state technology.

South Korea's Hyundai auto group aims to produce electric vehicles installed with solid-state batteries in 2025 through strategic cooperation with domestic and foreign battery makers. Hyundai showed its strong interest in a prototype pouch cell developed by Samsung researchers for high-performance, long-lasting all-solid-state batteries that would enable an electric vehicle to travel up to 800 kilometers (497 miles) on a single charge.

With solid-state batteries, faster charging, higher voltage and longer cycle life are possible. However, challenges to widespread adoption include energy and power density, durability, material costs, sensitivity and stability. Solid lithium metal anodes tend to suffer from the formation and growth of dendrites which can produce undesirable side effects and reduce a battery’s lifespan and safety.

Sulfide-based solid-state batteries use lithium metal as anode material to enable higher battery energy density and safety characteristics than lithium-ion batteries. However, a sulfide-based battery has degradation problems caused by filaments growing out of anodes or the interphase in solid sulfide-based electrolytes. Such side reactions shorten the lifecycle of a battery.

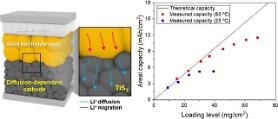

In July, the Electronics and Telecommunications Research Institute (ETRI) teamed up with the Daegu Gyeongbuk Institute of Science and Technology (DGIST) to develop a new electrode structure for an all-solid-state battery without using titanium disulfide (TiS2). The new structure features an active material made with highly compressed TiS2 and binders. The new structure can reach about 1.3 times higher in energy density than solid electrolytes.

-0-

Copyright ⓒ Aju Press All rights reserved.